Current location:Home -

Products center -

Acid treated graphite

Current location:Home -

Products center -

Acid treated graphite

- Acid treated graphite

-

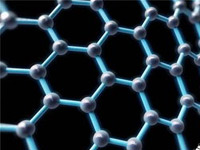

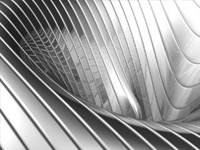

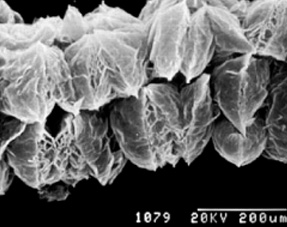

Acid treated graphite, also known as expandable graphite, refers to graphite that undergoes special oxidative intercalation and then rapidly expands into worm-like graphite under high temperature conditions. It has excellent flexibility and plasticity, and can be applied to graphite paper products and fire protection.

Expandable graphite as a flame retardant, the principle is: at a certain temperature, the graphite intercalation insert rapidly heated gasification, the formation of gas on the graphite sheet layer between the huge support tension, the rapid expansion of expandable graphite, the formation of worm-like On the one hand, heat absorption during the expansion process will reduce part of the thermal energy, and on the other hand, the formed expansion layer has a good thermal insulation effect, not only reduces the thermal energy radiated to the flame-retardant substrate, lowers the surface temperature, and inhibits the further degradation and burning of the substrate. It can also reduce the diffusion of combustible products and oxygen, inhibit or prevent the further spread of the flame.

Classification of acid treated graphite:

1, according to expansion: high expansion expandable graphite: (250-400 times) and low expansion expandable graphite: (100-240 times)

2. According to the processing method: potassium permanganate method, sodium dichromate method, hydrogen peroxide method, nitric acid method.

3, according to the sulfur content: sulfuric acid and nitric acid with low sulfur or sulfur-free method.

4. According to start temperature: low start temperature: 80-150 degrees

middle start temperature: 150-240 degrees

high start temperature: 300 degrees.

Meet requirements of different expansion rate and different purity .

Regular production of special products with low start temperature

Ultra-low trace elements and good stability

Address: Zhenning Road, Nanshu Town, Laixi, Shandong

Address: Zhenning Road, Nanshu Town, Laixi, Shandong Zip code:266613

Zip code:266613 Tel:0532-83431195

Tel:0532-83431195 Fax:0532-83431373

Fax:0532-83431373 E-mail:guangxingdianzi@qdguanging.com

E-mail:guangxingdianzi@qdguanging.com

QQ

QQ Tel

Tel Message

Message Share

Share Top

Top